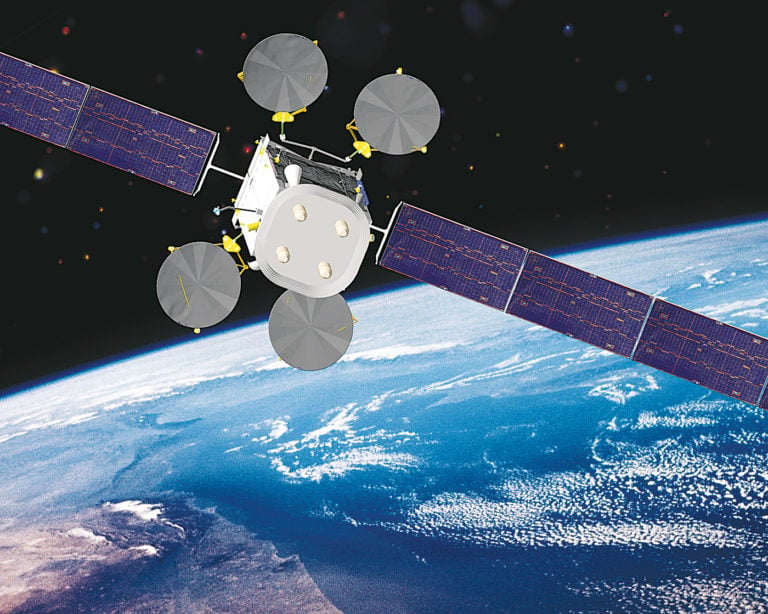

Boeing Co.’s completion of the “critical design review” phase of its latest satellite project means it’s ready to start building the orbiter at its El Segundo plant.

About 400 workers there have been assigned to the IS-22, a telecommunications satellite designed for Intelsat Ltd. in Luxembourg.

The new satellite is noteworthy in at least two respects. First, its design innovations, Boeing said, will make it “faster to build, less costly and more efficient in operation” as well as potentially longer-lasting.

Secondly, in addition to its telecom section, the satellite will carry a UHF payload built by Boeing but paid for by the Australian Defense Force, which is leasing space on the IS-22 for military communications.

Though governments have previously leased private satellite space, said Keith Volkert, chief executive of Satellite Consulting Inc., an aerospace consulting service in Palos Verdes Peninsula, it’s never been done on this scale.

“This is a big deal,” Volkert said. “It opens up all kinds of possibilities for new applications in space that were not necessarily viable before.”

A Boeing spokeswoman said the satellite – which will also provide commercial video, network and voice services to Intelsat customers throughout the Indian Ocean region – is expected to be ready for launch sometime in 2012.

Completion of the design review was a key milestone in the project.

“This is very exciting,” spokeswoman Angie Yoshimura said. “To have completed this review is great for our customer and important for Boeing.”

The design review, during which Boeing and Intelsat engineers closely analyzed the satellite plan, took place between July 7 and July 15.

“They were looking at everything from assembling it to integrating all those parts to make a whole,” Yoshimura said.

The IS-22 is the first of four satellites commissioned by Intelsat from Boeing in a deal that some media outlets have speculated could be worth $1 billion. The company has rejected that figure, but declines to reveal the actual number.

‘Manufacturing-Lite’

Rather than build a factory, a small Santa Clarita startup with the mission of making solar panel parts out of castor bean oil has decided to outsource its production.

BioSolar Inc. recently announced that it will employ a “manufacturing-lite” model in creating renewable solar casings designed to replace those currently made from petroleum-based products.

“Our scarce resources need to be invested in what we do best – which is innovation – instead of spending $15 million to $20 million on a manufacturing facility,” said David Lee, chief executive of the four-year-old firm.

So the startup will outsource its manufacturing and distribution to other companies, most notably Rowland Technologies in Wallingford, Conn. BioSolar specializes in designing solar panel parts, including the back sheets that help house and protect solar cells. Such parts are traditionally made from silicone, but BioSolar makes them from a polymer derived from castor bean oil.

As a result, Lee said, the manufacturing process is less toxic and more environmentally friendly.

Though the company has supplied a large number of samples to solar panel manufacturers that are testing them, he said, it has not yet announced any sales.

“We’re probably looking at 2011 before we can comment on specific customers and volumes,” he said.

Zero Gravity

Technology adapted from the movie industry has earned a Hollywood company an international innovation award.

Equipois Inc. received a 2010 International Stevie Award for Most Innovative Company of the Year in North America for designing and manufacturing machinery that makes 40-pound tools act as if they were weightless.

“Factory workers can now operate literally as if they’re in space,” said Eric Golden, the company’s chief executive.

Golden said the patented workplace technology – called “zero gravity” – can increase a factory’s productivity as much as 50 percent while reducing the number of work-related accidents.

Adapted from the Steadicam, which allows cinematographers to capture scenes without having the images appear jostled even as cameras move during shooting, the technology consists of a system of springs and cams that helps workers handle heavy tools, parts and machinery with a minimum of weight resistance.

“It offers full freedom of motion without the effort required to lift,” Golden said. Among the companies using the technology are Honda, Toyota, Ford, Boeing, Lockheed Martin and Caterpillar.

Equipois was one of 133 honorees selected from among 1,700 entries in 40 nations by the Stevie Awards, an independent organization based in Fairfax, Va. The contest, judged by leading business figures, was created in 2002 to recognize the accomplishments of companies and business people worldwide.

The only other L.A.-area winner in the international division was Oakwood Temporary Housing, which was cited for best hiring and recruiting program as well as best sales process.

Staff reporter David Haldane can be reached at [email protected] or at 323-549-5225, ext. 225.